|

Grade

|

A356 A360 AC2C

|

|

Product weight

|

From 0.05kg to 20kg

|

|

Heat Treatment

|

T6 Heat Treatment Continue

|

|

Surface finished

|

Sandblasting, painting, polishing,powder coating

|

|

Applied software

|

Pro/E,Auto CAD,Solid Work ,CAXA, UG, CAD/CAM/CAE

|

|

Machining equipments

|

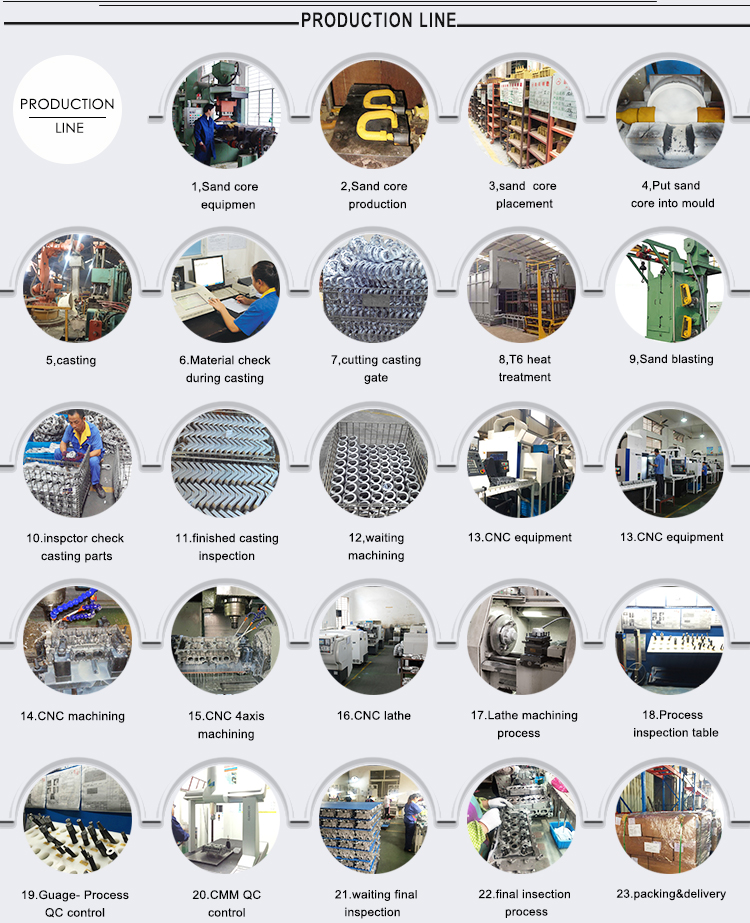

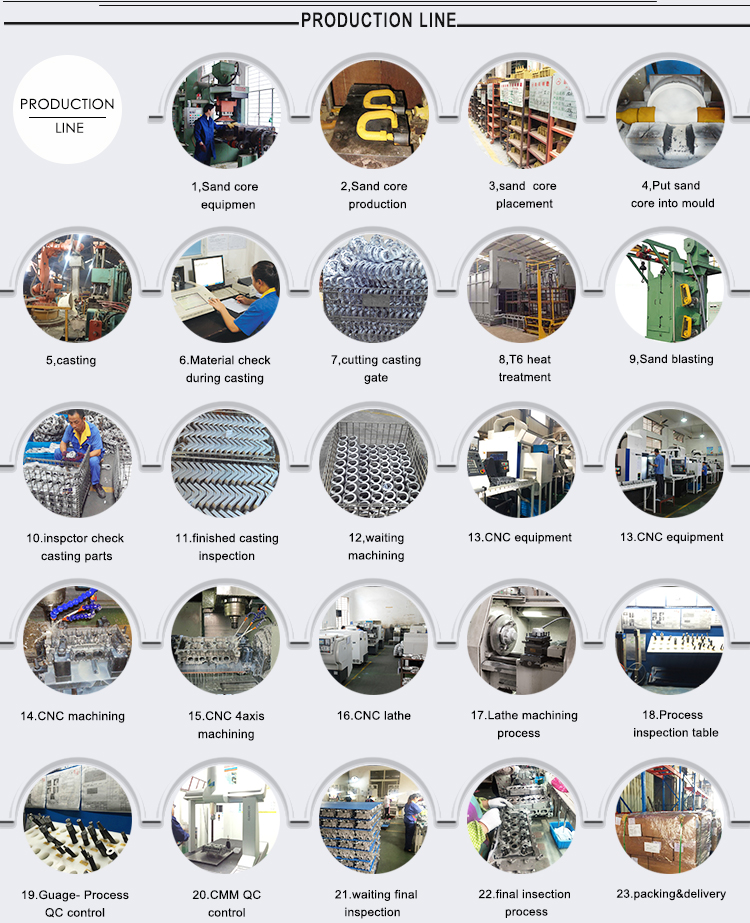

Gravity Casting machine -23 Sets

Sand Core machine -15 Sets

Continue T6 heat treatment machine-1 sets

Sand blasting machine-3 sets

CNC -80 sets

CNC Lathe- 25 sets

Drilling machine - 100 sets

|

|

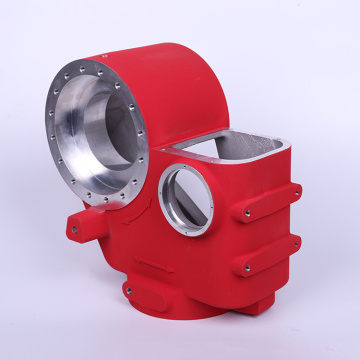

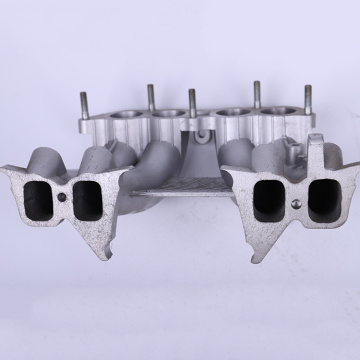

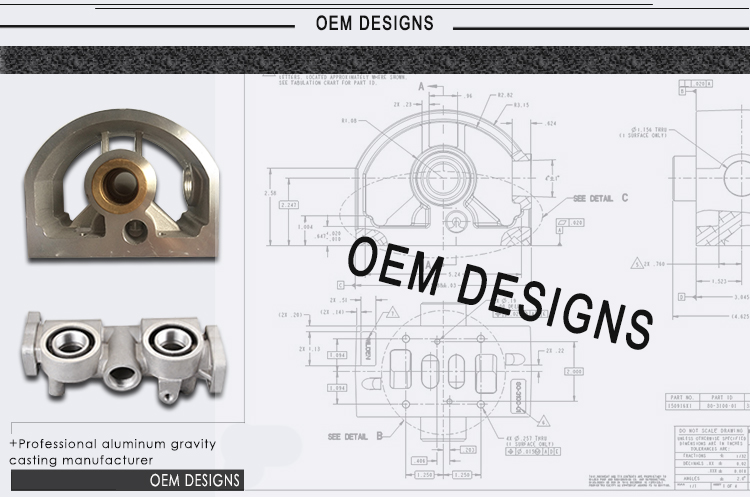

Main products

|

Intake Manifold series,Cylinder Head series and Pump series

Train spare parts and all kinds of aluminum casting parts

They can be produced according to customers’ designed drawings

|

|

Service

|

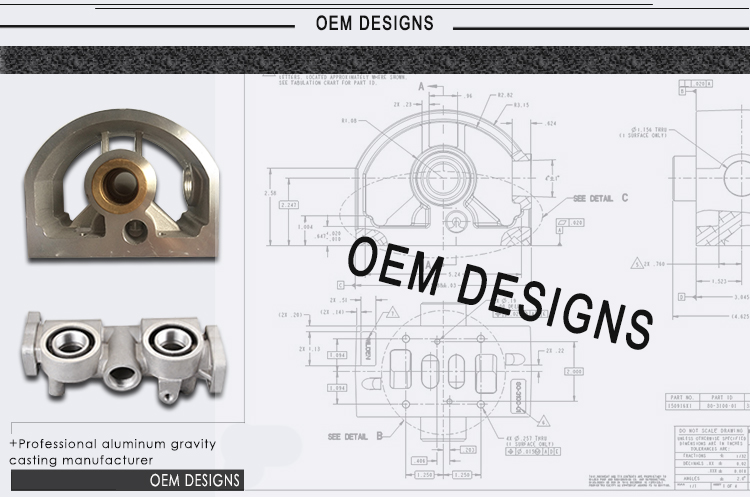

OEM service available

|

|

Machine Name

|

Brand & Model No.

|

Quantity

|

Number of

Year(s) Used

|

Condition

|

|

Coordinate Measuring Machine

|

754T-M, HEXAGON

|

2

|

3

|

Acceptable

|

|

Spectrum Analyzer

|

METALSCAN-2500

|

1

|

4

|

Acceptable

|

|

Tool Preseting Measuring Instrument

|

ET-300H

|

1

|

4

|

Acceptable

|

|

Electronic Pull Tester

|

LDS-W50A

|

1

|

5

|

Acceptable

|

|

Sand Intensity Machine

|

XQY

|

1

|

4

|

Acceptable

|

|

Automated Polishers

|

P-2

|

1

|

4

|

Acceptable

|

|

Hardness T ester

|

HR-150A

|

1

|

4

|

Acceptable

|

|

Torque Wrench Calibrator

|

Zhunda

|

1

|

1

|

Acceptable

|

|

Metalloscope

|

ikowan

|

1

|

3

|

Acceptable

|

|

Air-Tightness Tester

|

LS-1863X

|

8

|

2

|

Acceptable

|

|

Machine Name

|

Brand & Model No.

|

Quantity

|

Number of

Year(s) Used

|

Condition

|

|

Core Shooting Machine

|

JL6G35

|

23

|

4

|

Acceptable

|

|

Pouring Machine

|

NZJ630Q

|

15

|

4

|

Acceptable

|

|

Mechanical Arm

|

ABB

|

2

|

3

|

Acceptable

|

|

Shot Blasting Machine

|

Q37, Z-PW001

|

3

|

7

|

Acceptable

|

|

CNC Lathe

|

CJK6132

|

19

|

6

|

Acceptable

|

|

Machining Center

|

J-JG001, F500

|

80

|

4

|

Acceptable

|

|

Cleaning Machine

|

ZQZ, J-QX002

|

5

|

3

|

Acceptable

|

|

Heat Treating Furnace

|

HJJX-25

|

1

|

1

|

Acceptable

|

|

Drilling Machine

|

ZS4116

|

40

|

6

|

Acceptable

|

| Company Building Information |

...................................................... ...................................................... ......................................................

Tipo de certificación: el oficial de fábrica reclamó

Tamaño total del edificio: 8,981m 2

Número de edificios: 5

Tamaño de la oficina: 500m 2

|

Product Name

|

Production Line Capacity

|

Actual Units Produced (Previous Year)

|

|

Aluminium Gravity Casting Parts

|

45,000 Pieces / Month

|

35,000 Pieces / Month

|

|

Production Capacity:

1: 2 set ABB Robotic arm arm for auto cast cylinder head mould.

operation 6 set moulds for cylinder head,/2 shift/1200pcs each day.

Average 20Tons aluminum each day.

2: Traditional casting:

Flexible replacement of different mould casting.

2 shift operation for 10~20 kinds of item.

Total 1000~2000 piece parts is casting capacity each day.

3: Machining:

For Cylinder Head:(A,B,C,D,E,F) six lean production lines for machining cylinder head.

24hours working.

Total finished machining part1000pcs and shipment 1000pcs each day.

For Export Part:

15 sets CNC machine can be 24hours working for several hundred different part.

There are flexible replacement in production.

More than Tens of thousands of different export part on each month.

Total 1000~2000piece parts finished each day.

|

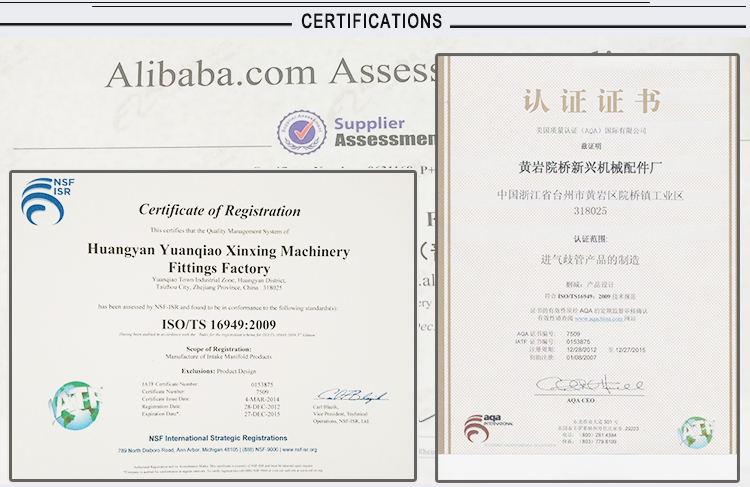

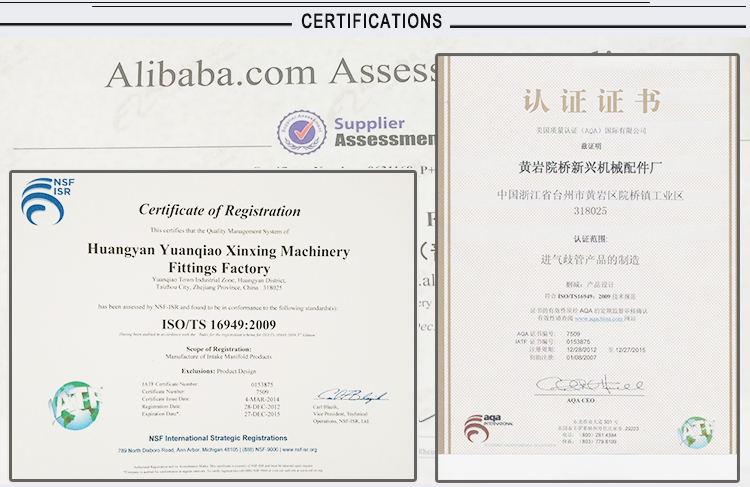

Quality Management System Certification

|

|

Certification

|

Certified By

|

Certificate No.

|

Business Scope

|

Validity Date

|

|

ISO / TS

16949:2009

|

AQA

International

IATF

|

7509

|

Manufacture of Intake Manifold

Cylinder Head Products

|

28/Dec./2012 --27/Dec./2015

|

|

Market

|

Revenue(previous year)

|

Total revenue(%)

|

|

North America

|

$1,686,667

|

10.12%

|

|

Eastern Europe

|

$93,333

|

5.36%

|

|

Western Europe

|

$1,018,333

|

6.11%

|

|

Northern Europe

|

$586,667

|

3.52%

|

|

Domestic Market

|

$12,481,667

|

74.89%

|